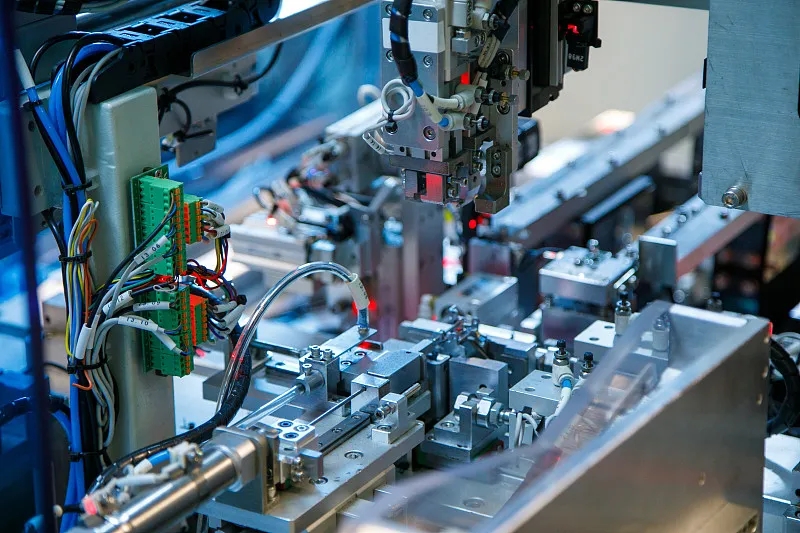

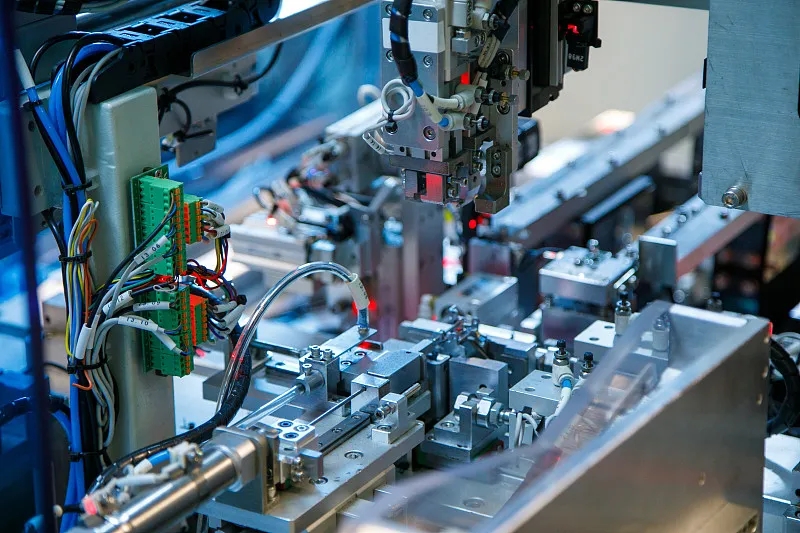

We can develop and provide a complete set of essential components for machine tools. The ultimate performance is the constant demand for precision bearings in machine tools. The ultimate is art. We are committed to fully extending the precision life of bearings, continuously promoting the application of key technologies for long-life smart bearing steel, and combining friction theory and lubrication theory to continuously reduce energy consumption, making precision machine tool bearings widely used by our machine tool users. The digitalization of the machine tool industry leads the industry process, and equipment standards based on geometric accuracy, motion accuracy, transmission accuracy, and dynamic accuracy have become important indicators for evaluating machine tool accuracy. As the core mother machine of industrial production, its performance has a profound impact on the productivity and competitiveness of enterprises.

Machine tools are the carrier of advanced manufacturing technology and the basic production means of equipment industry. They are the basic equipment of equipment manufacturing industry, mainly serving industries such as automobiles, military industry, agricultural machinery, engineering machinery, power equipment, railway locomotives, ships, etc. The machine tool industry has strategic importance in both economy and technology, and its equipment design capability and manufacturing process level based on mechanical engineering technology and digital control technology make it at the forefront of the Fourth Industrial Revolution. With digitization becoming the core driving force, exciting opportunities for further automation have emerged. The key goal of optimizing overall equipment efficiency, with reliable performance and sustainability at its core, is more important than ever before.

Bearings have high operating accuracy, high-speed performance, and high system rigidity, making them an ideal choice for machine tool spindle units. At the same time, the design of this bearing can also reduce noise, vibration, and heat generation. Various types, series, designs, variations, and sizes of ultra precision bearings are combined with optimal design to improve equipment performance, machine running time, speed, and accuracy. To meet the environmental requirements in recent years, a grease supply system was first introduced for the special bearings of machine tool spindles, and in the high-speed field that could only be achieved by lubricating oil in the past, a method of lubricating with grease was also realized. Various types, series, designs, variations, and sizes of ultra precision bearings are combined with optimal design to improve equipment performance, machine running time, speed, and accuracy.