-

-

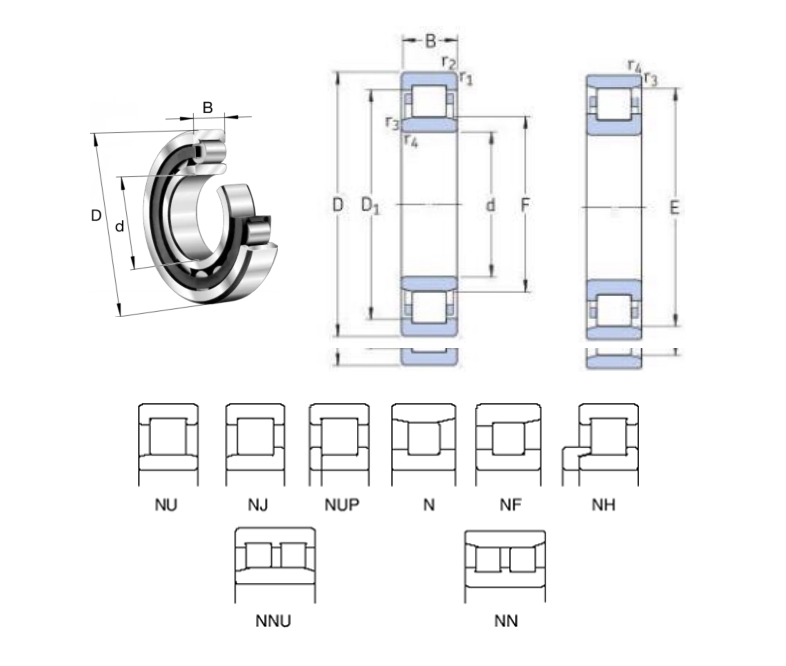

N series cylindrical roller bearing

JFU cylindrical roller bearings have various structures, such as N-type, NU type, NUP type,

NF type, NJ type, etc. After special optimization design, the rollers are in line contact with

the raceway, with high load capacity, mainly bearing radial loads, and having high bearing

capacity and ultimate speed. They can be used for fixed end support or floating end support.

● High load-bearing capacity and high rigidity

● Multiple cage designs

● Separable and interchangeable

● Long service life-

0.000.00

-

JFU cylindrical roller bearings have various structures, such as N-type, NU type, NUP type,

NF type, NJ type, etc. After special optimization design, the rollers are in line contact with

the raceway, with high load capacity, mainly bearing radial loads, and having high bearing

capacity and ultimate speed. They can be used for fixed end support or floating end support.

● High load-bearing capacity and high rigidity

● Multiple cage designs

● Separable and interchangeable

● Long service life

Product Introduction

The rolling elements of cylindrical roller bearings are cylindrical rollers, which belong to separable bearings. The rollers are in linear contact with the raceway, with a high load capacity, mainly bearing radial loads. The friction between the rolling elements and the ring edge is small, suitable for high-speed rotation, and high coaxiality is required during use. Cylindrical roller bearings with inner or outer rings without retaining edges, whose inner and outer rings can move relative to each other in the axial direction, can be used as free end bearings. A cylindrical roller bearing with dual flanges on one side of the inner and outer rings and a single flange on the other side of the ring can withstand a certain degree of unidirectional axial load. There are various structures, such as N-type, NU type, NUP type, NF type, NJ type, etc., which have been specially optimized to have high load-bearing capacity and ultimate speed, and can be used for fixed end support or floating end support.

Characteristics and advantages

● High load-bearing capacity and high rigidity

The rollers are in linear contact with the raceway and have high radial load-bearing capacity and rigidity. Special modification and optimization design have been carried out on the retaining edge and roller end face, further improving the axial bearing capacity of the bearing and reducing friction.

● Multiple cage designs

Nylon retainers, steel retainers, and brass retainers can be used. Nylon cages have the advantages of low friction coefficient, light weight, and low noise, while metal solid cages have higher strength.

● Long service life

The contour modification of the logarithmic curve of the roller reduces the edge stress at the contact between the roller and the raceway, and also improves the bearing's ability to adapt to misalignment between the shaft and the bearing seat.

● Improve operational reliability

Optimizing the surface machining quality of rollers and raceways is more conducive to the formation of lubricating oil film and improves the dynamic performance of bearings.

● Separable and interchangeable

Cylindrical roller bearings have high machining accuracy, and the separated rings can be interchanged.

Product Application

Large and medium-sized electric motors, locomotives, machine tool spindles, internal combustion engines, generators, gas turbines, gearboxes, rolling mills, vibrating screens, and lifting and transportation machinery.

JFU is committed to providing customers with affordability and convenience. We aspire to become strategic partners, helping clients grow and achieve mutual success!